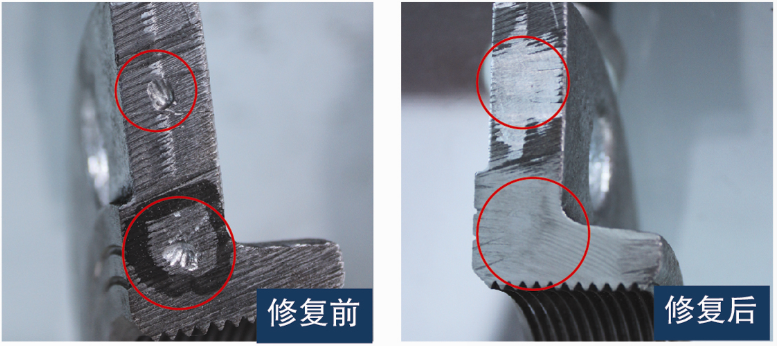

Effect drawing of welding repair of iron castings:

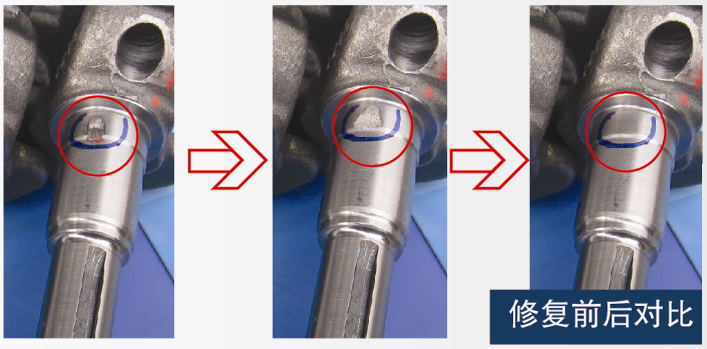

Effect drawing of steel casting welding repair

1. More advanced core technology

The electric spark surfacing repair machine uses the high temperature generated at the moment of discharge to melt the welding materials in an instant (10us-100us) and metallurgical bond with the substrate under the action of various forces. The equipment is not only a high-frequency switching power supply controlled by current source PWM to ensure its working stability, but also uses microprocessor (MCU) to accurately control the discharge current and discharge time, so as to control the input heat to achieve the effect of cold welding, and the output voltage is adjustable. Its welding efficiency is more than twice that of similar welders in the market, The work efficiency has reached an amazing 95%.

2. The welding repair efficiency is more than twice that on the market

The electric spark surfacing repair machine adopts double end flow control technology and energy recovery technology, so its welding repair power is more than twice that of other similar welding machines in the market. So save you a labor cost!

3. More professional technical training

Our company has professional technicians responsible for on-site training to ensure the perfect welding repair effect of products, and technicians will analyze all products of the company and adopt the most ideal welding repair technology to improve the production efficiency of customers. Other companies only conduct simple training, or even telephone training.

4. The first digital storage function repair equipment in China

Our company's equipment has digital control and powerful storage function. It can store a variety of welding repair modes, which greatly improves the work efficiency. It is the first EDM surfacing repair machine to realize digital storage function in China

简体中文

简体中文