简体中文

简体中文

Precision cold welding:Also known as stainless steel cold welding machine, mold repair welding machine, ultra laser cold welding machine, multi-functional cold welding machine, etc., it is mainly used in metal welding, mold repair, shaft repair and other industries;

No deformation and discoloration can be achieved on the welded sheet metal, and the general worker can operate easily;

On the welding repair mold, no undercut, no annealing and no damage to the matrix structure can be achieved. It is convenient and fast to repair after removing the mold.

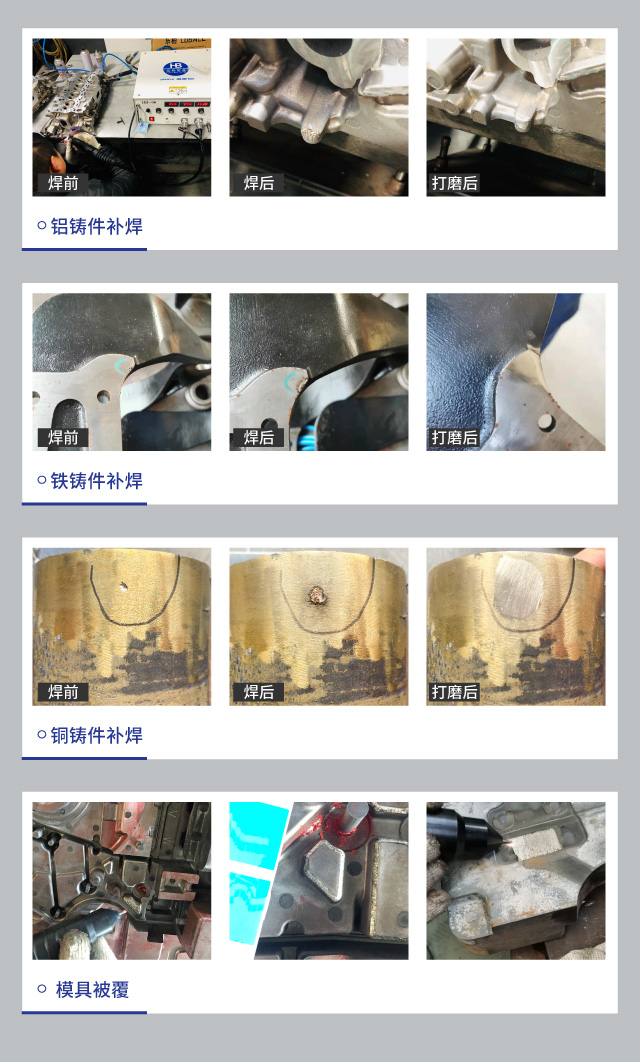

Electric spark cold welding machine:Also known as casting defect repair machine, mold coating machine, etc., it is mainly used in casting, machining, casting and other industries;

In the repair of defects such as air holes, sand holes and shrinkage holes of castings, no undercut, cracking, color difference and hard spots can be achieved, and secondary processing can be carried out in the later stage;

In terms of die coating strengthening, it can improve the service life of the die by 3-5 times, and solve the problems of die sticking, die drawing, lack of material and so on。

Working principle of precision cold welding machine:

Through microcomputer technology, the welding time is accurately controlled, so that the converted electric energy is instantly released between the tungsten electrode and the workpiece in the form of pulse arc. The extremely high temperature arc makes the workpiece and welding wire composed of metal materials melt and weld together quickly, so as to achieve the purpose of cold welding。

Working principle of electric spark cold welding machine:

Using the working principle of deposition surfacing, the high-energy electric quantity stored in the power supply is instantly released at high frequency between the welding wire and the base metal. Through the gas ionization between the welding material and the base metal, multiple micro arc channels are formed to produce instantaneous high-temperature micro areas on the surface of the base metal. The welding material is fused to the surface of the base metal under the action of micro electricity to form metallurgical bonding。

After more than ten years of precipitation, our company has passed ISO9001 quality system certification and a number of patents in the industry, and has been rated as an AAA credit management enterprise

This page is just a brief introduction to the concept of cold welding machine. We have professional technicians who will select the products for you. The national free consultation hotline is 400-800-8257。