简体中文

简体中文

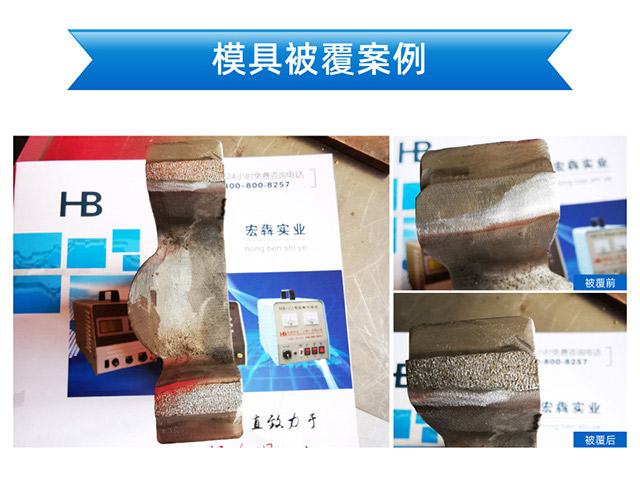

1. Applicable to impact resistant molds (metal molds such as stamping mold, die casting mold, injection mold and rubber mold), which can increase the service life by 200% - 300%.

2. Suitable for high temperature resistant contact surface (die casting, aluminum film casting mouth, etc.), which can increase the service life by 200% - 300%.

3. It is applicable to the surface coating of cutting tools and cutting tools (turning tools, drill bits, milling cutters and other metal processing tools), which can increase the service life by 300% - 500%.

4. It is applicable to the surface coating of various fixtures and collets to increase wear resistance and prolong service life。

Equipment characteristics

◆ the thickness and thickness of the coating can be adjusted arbitrarily, and the standard thickness is 0.01-0.1mm;

◆ the notch of stamping die is covered with superhard alloy, which can prevent chip jumping in production and ensure the smooth processing of punch;

◆ it can be strengthened repeatedly to improve the service life of the mold and enhance the demoulding performance;

◆ in the process of die coating, the matrix does not need to be preheated. When the die is coated at room temperature, the matrix does not heat, does not produce thermal deformation, does not crack, and the metallographic structure near the coating area does not change and there is no stress concentration;

◆ the problem of die drawing and die sticking is solved. After coating, it can be used without treatment, and the coating can be repeated for many times;

◆ die sticking and material sticking during the use of die-casting molds can be directly produced on the machine without any treatment after coating;

◆ environmental protection equipment without any pollution during operation;

◆ it is easy for anyone to use and operate without operation certificate.