Automatic inner hole welding machine is a newly developed equipment for defect repair of metal inner hole products developed by Hongyu industry (Shanghai) Co., Ltd. It can carry out welding repair and cladding for valves, valve bodies and circular inner walls of various castings. The equipment has the advantages of no deformation, no porosity and adjustable hardness of the repair layer. The equipment does not need manual operation and fully automatic welding repair。

1、Equipment characteristics:

The automatic inner hole welding machine adopts imported linear guide rail, precision worm gear reducer and stepping motor to drive and walk, and the whole machine runs stably and integrates simply;

The automatic inner hole welding machine is equipped with weld height tracking device, so that there is no need to worry about the height problem in the process of inner hole welding repair, and it can be repaired automatically with one key setting。

2、Applicable products of automatic inner hole welder:

Repair the damage, defect and burr of the inner hole of the die, valve and shaft sleeve;

The wear resistance, heat resistance and corrosion resistance of the inner wall of precision parts are strengthened.

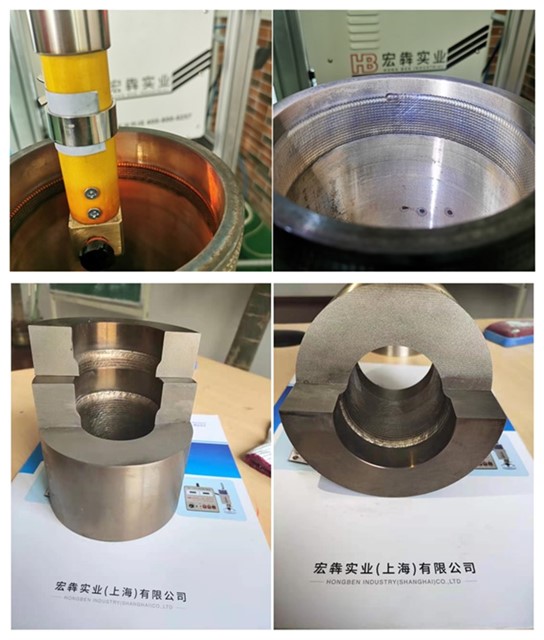

3、Effect of automatic inner hole welder:

4、Hongzhen automatic inner hole welding machine has advantages over other similar welding machines:

1. Stable and reliable product quality: China selects the best accessories to make the whole cold welding cladding system more stable and reliable!

2. Low heat: the cold welding process is adopted to lower the temperature after welding and will not damage the matrix!

3. Safer: the cold welding process makes the welding process no noise, less splash or even no splash, with minimal harm to human body!

4. The after-sales warranty lasts longer: give a solution in two hours and solve the problem in 48 hours!

5. More perfect after-sales service: then we are one of the first enterprises in China that promise to guarantee the host for two years!

简体中文

简体中文