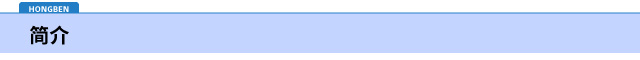

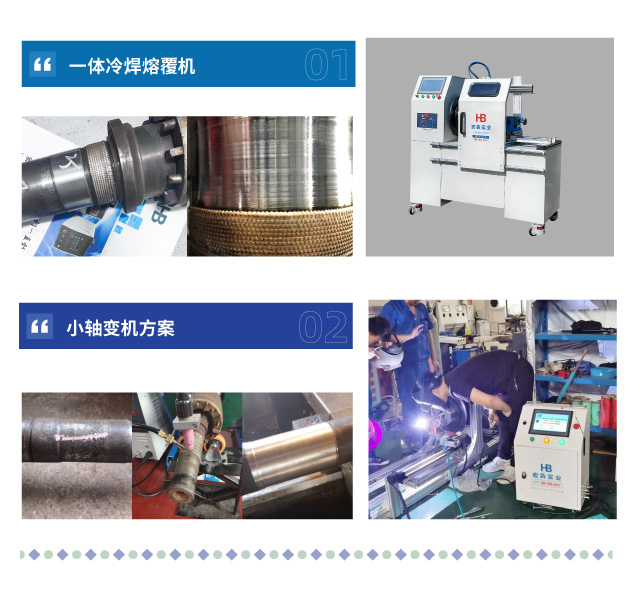

Low temperature cladding equipment

Low temperature cladding equipment is a repair welding equipment developed for different defects (such as bump, scratch and wear). Manual or automatic repair welding can be selected for defects of different sizes. It is mainly used for repair welding of inner hole / outer diameter defects of circular workpieces such as shafts.

For different defects, it can be divided into manual repair welding, automatic repair welding and inner hole repair welding

- It is mainly aimed at repairing defects such as broaching, pinhole, pinhole and local wear. Generally, manual repair welding is adopted, and traditional welding wire is selected for repair with cold welding equipment

- Customized service: according to the customer's product situation, we can cooperate with the customer's machine tools and other ancillary equipment to make customized services

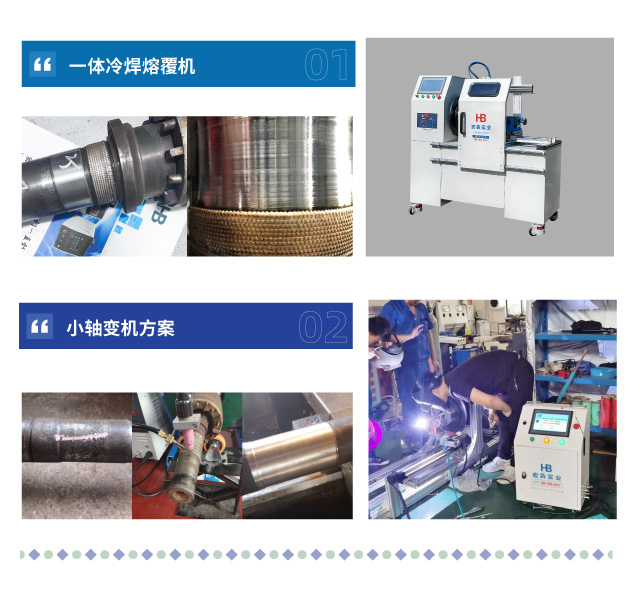

- Small shaft repair welding can be carried out by integrated cold welding cladding equipment or positioner cladding device, which is convenient and fast

- Medium / long shafts: the old lathe / roller carrier and other auxiliary devices can be refitted for automatic repair welding, which is economical, flexible and convenient

- Large shafts: auxiliary devices such as roller frame / idler can be used for repair welding, which solves the problem that large shafts cannot be repaired automatically

- Inner hole repair welding: welding repair and cladding can be carried out for the circular inner wall of valves, valve bodies and various castings. The equipment has the advantages of no deformation, no porosity and adjustable hardness of the repair layer. The equipment does not need manual operation and fully automatic welding repair。

- We can provide customized solutions for different workpieces. Please contact us for details:+86 18201899096

简体中文

简体中文