简体中文

简体中文

3、 Conventional welding machines commonly used in the market:

Large heat affected area

The workpiece is easy to deform and reduce hardness after repair

Annealing undercut occurs locally

Insufficient bonding force and internal stress damage

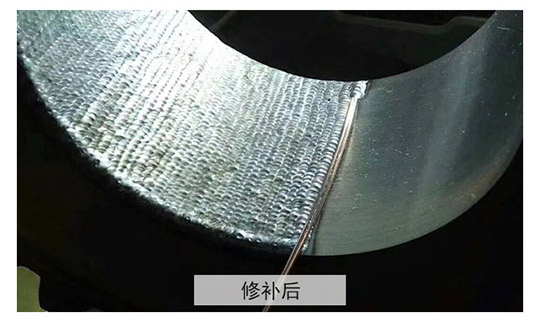

4、 Advantages of Hongyu precision cold repair welding machine:

1. No annealing, deformation and undercut after repair;

2. The operation is convenient and simple, and the general workers can also get started easily;

3. The properties of welding material and base metal will not be changed after welding;

4. High repair accuracy without losing the original datum;

5. The repair speed is fast, and the fastest repair amount can reach 100mm3 / min;

6. Small damage to the substrate and small hot spots;

7. Wide voltage adaptation range, with voltage variation of & plusmn; When it fluctuates within 20%, the machine can still work normally and maintain stable output power;

8. Easy to carry, small size, light weight and low power consumption;

9. The formed stress is small and can be processed in the later stage.